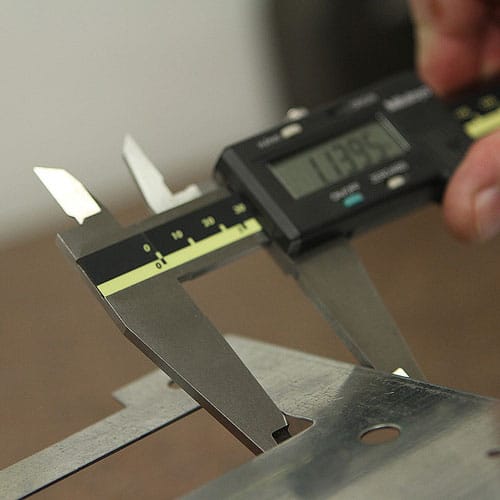

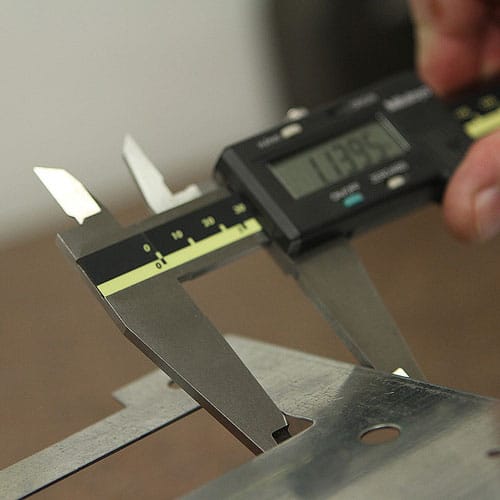

Meeting high-tolerance requirements

Custom Sheet Metal Fabrication

Cutting-edge technology, equipment, and specialized operations

From concept to completion, we specialize in crafting high-quality components tailored to your project’s exact specifications.

Our ISO 9001:2015 registered manufacturing 110k sq. ft. facility is equipped with advanced technology and specialized operations, guaranteeing superior results. Trust us as your single-source partner for cost-effective, high-quality sheet metal solutions.

Advanced Metal Fabrication Applications

Components Manufactured with Sheet Metal Fabrication Techniques

DATA CENTER FIXTURES

With data processing and computing transitioning to cloud-based systems, the demand for efficient earth-bound infrastructure is on the rise. Schaffer Manufacturing meets this need with our single-source, high-volume sheet metal fabrication services tailored for the future of data.

Our lean—and cell-based manufacturing operations ensure the streamlined production of server rack components and assemblies, delivering efficiency and scalability to rapidly expanding data centers.

Data Center

Fixtures

▼

We offer a comprehensive range of fabrication and assembly services, providing a single-source solution for your data center fixture needs. Our proven strategies, from material utilization to inventory management, guarantee cost-effective solutions without compromising quality. In addition to our fabrication capabilities, Schaffer Manufacturing offers engineering, design for manufacturability, and prototype services. Our ability to scale up to volume production and provide efficient inventory management ensures that we can meet the needs of your data center infrastructure.

Enclosures

▼

While enclosures are often seen as standard supply chain purchases, our approach challenges this perception, unlocking opportunities for value addition across the board. From supplying frames and skins for OEM products to crafting protective housings for power-system components and stainless-steel constructions for food industry applications; Our expertise extends beyond basic operations, encompassing complex specifications, intricate weld quality, and impeccable cosmetic finishing. We optimize fabrication processes to minimize labor-intensive operations like welding and assembly, ensuring efficiency without compromising quality. With our single-source versatility, we partner with you at every stage, from prototype to production volumes. Whether it's mild steel or stainless steel, we have the capabilities to meet your enclosure metal fabrication needs.

Packaging Processing

▼

In today's fast-paced market, the evolution of packaging and material processing equipment is relentless, driven by the demand for increased speed, efficiency, precision, and flexibility. Schaffer Manufacturing partners with automated packaging and materials processing OEMs on solutions ranging from foods and confectionary systems to laser-based die-cutting, laminating, and converting machines. Our comprehensive approach ensures that every component is meticulously crafted to deliver optimal results. From fabricating frameworks and components to applying quality metal finishes and managing inventory, we offer a comprehensive suite of services to support our clients' success. With our expertise in working extensively with stainless steel and cutting stock over ½” thick using advanced technology like the 5000-watt fiber laser, we deliver solutions that combine speed, precision, and automation for unparalleled performance.

Quality Control

▼

As technology for product testing advances, there is an increasing demand for sophisticated design and engineering of equipment that simulates environmental and stress conditions, extending to the fabrication of test systems that are essential for the development of high-performing products. Schaffer Manufacturing specializes in the fabrication and assembly of complex chamber-type enclosures, including frames, stainless steel skins, insulating materials, gaskets, and hardware. These enclosures are used to test products under real-world scenarios, ensuring they meet high-quality standards and performance expectations. Fabricating sophisticated test equipment requires seamless vertical integration. From precise laser and water jet cutting to careful forming, standardization of assembly steps, and applying powder coating for lab-quality appearance, Schaffer employs fabrication strategies that align with evolving product test technology.

Retail Fixtures

▼

We recognize the significance of retail fixtures in shaping the consumer experience. Whether it's point-of-purchase displays or commercial environments, metal fabrication plays a crucial role in bringing concepts to life. At Schaffer Manufacturing, we partner with retail fixture designers and use material, design manufacturability, and metal fabrication strategies that help a vision come to life as cost-efficiently as possible. Store environment designers and retail/commercial customers can trust Schaffer to strike the perfect balance between form, function, quality, and cost management. Our commitment to delivering exceptional results is evident from concept development to final assembly. As a single-source solution for store fixture fabrication, Schaffer offers a comprehensive range of services, including sheet metal laser cutting, forming, powder coating, and assembly.

“Schaffer turnaround can be up to 40% faster than the 10-week lead times typical for large, heavy fabrication projects.”

CONTACT US TODAY

Leverage our expertise for your project success.

Partner with us and benefit from our extensive toolkit, industry-specific experience, and reliable processes and systems you can trust to convert metal fabrication requirements into product manufacturing wins.

Phone: (715) 825-2424

Address: 109 Industrial Ave, Milltown, WI 54858

- Monday - Friday 6AM–4:30PM

- Saturday - Sunday Closed

CONTACT US TODAY

Leverage our expertise for your project success.

Partner with us and benefit from our extensive toolkit, industry-specific experience, and reliable processes and systems you can trust to convert metal fabrication requirements into product manufacturing wins.